June 14, 2018

Deaths and diseases due to silica dust exposure are 100 percent preventable. That's why OSHA changed its standards on silica in 2016, updating regulations from the 1970s to lower the amount of acceptable exposure in accordance with more recent research.

OSHA estimates that over 2 million workers are exposed to silica dust each year. Because so many people are affected, the National Institute for Occupational Safety and Health (NIOSH) has been recommending stricter regulation for several years.

The new regulation provides flexible compliance dates to employers. Enforcement for construction industry regulations began in September 2017 and enforcement for general industry and maritime operations is scheduled for June 23, 2018. With hydraulic fracturing technology still in development, enforcement for this industry is not scheduled until June 23, 2021.

What exactly is silica and why is it hazardous?

A single grain of salt is 60 times larger than a particle of silica dust. These microscopic dust particles cause scar tissue that impairs lung function by reducing the ability to take in oxygen. This impaired lung function can lead to lung cancer, silicosis, chronic obstructive pulmonary disease and kidney disease. Silicosis contributes to around 100 deaths per year according to NIOSH. And it also makes workers more susceptible to other lung infections, such as tuberculosis.

Silica is a naturally occurring mineral that is found all over the planet. It's found in materials like sand, soil and granite. It’s used to make products such as glass, concrete, bricks and artificial stone. If it’s not being disturbed, then it’s not hazardous. But, any operation that involves cutting, crushing or pulverizing materials that contain silica will create tiny particles of silica dust - or crystalline silica, which has been classified as a human lung carcinogen.

Watch the video below to learn more about silica and its dangers.

How do you know if you have a silica exposure?

Any job that involves cutting or drilling into materials like sand, soil or granite could have a silica exposure. Other examples are sand blasting to remove rust, cutting bricks, jackhammering, well drilling, any type of tunneling operation or working on railroad track. Some of the more common operations that produce silica dust are glass and concrete products, abrasive blasting, painting and coating, foundries, dental laboratories and jewelry production.

Depending on any given worker's health and amount of exposure, symptoms could appear after a few months or not until 15 or 20 years later. Other health concerns like smoking can add to the damages caused by silica particles and accelerate the symptoms. There is no cure for silicosis and it's a progressive disease. This means that it grows worse, even if there is not continued exposure.

With any overexposure of silica, a chest x-ray should show lung damage. But aside from that, lower exposures may not show obvious symptoms for years. A chronic dry cough and shortness of breath during physical activities are likely to appear as early symptoms of silica exposure. Lower or moderate exposures generally lead to fatigue, weakness and weight loss. But the higher the exposure, the more disabling the symptoms. High exposures can lead to severe shortness of breath and respiratory failure, which can be fatal.

What changed with OSHA's new silica standard?

The most important provision of the new silica standard is that it reduces the permissible exposure limit (PEL) for silica dust. The PEL is the maximum amount of silica exposure legally allowed for a worker. The previous PEL for the construction industry was 250 micrograms per cubic meter time weighted average, and the previous PEL for general industry was 100 micrograms.

As far back as 1978, NIOSH has been recommending that the PEL be reduced to 50 micrograms per cubic meter, and now this standard is averaged over an 8-hour day. To this end, OSHA has established an action level of 25 micrograms of silica per cubic meter. If an employee is exposed at this level, they are more than halfway to the maximum legal exposure. This means that there is a possibility that they could be overexposed in certain conditions or on certain days, so OSHA requires some control measures to be in place.

What does OSHA require employers to do to keep employees safe?

Employers are responsible for knowing if employees are exposed to silica, training them on the hazards and providing proper protections. In the new standard, OSHA outlines employer requirements as summarized below.

Use engineering controls as a primary means of limiting employee exposure to silica.

This means that engineering controls must be attempted first, rather than simply using respirators. Engineering controls might consist of using water delivery systems that would feed water to the saw blade while cutting or using a dust collector with a filter. The engineering controls will differ according to the work task or tool being used.

Provide respirators when engineering controls cannot adequately limit exposure.

This means determining the proper respirator, purchasing it and providing fit testing and medical evaluations when necessary. This also means training the employee on the use and maintenance of their respirator.

Limit worker access to high exposure areas.

Employers need to post warning signs and make sure that employees are not performing tasks in a high-exposure area for more than a permissible amount of time.

Develop a written exposure control plan.

Employers should describe the silica hazards and how they are being controlled.

Medical exams must be offered to highly exposed workers.

The medical exam would be specific to silica exposure such as a chest x-ray and pulmonary function test.

Train workers on the risks of silica exposure and the control measures the company has implemented.

Above all, OSHA says companies need to prevent employees from breathing in air that has more than 50 micrograms of respirable silica dust per cubic meter.

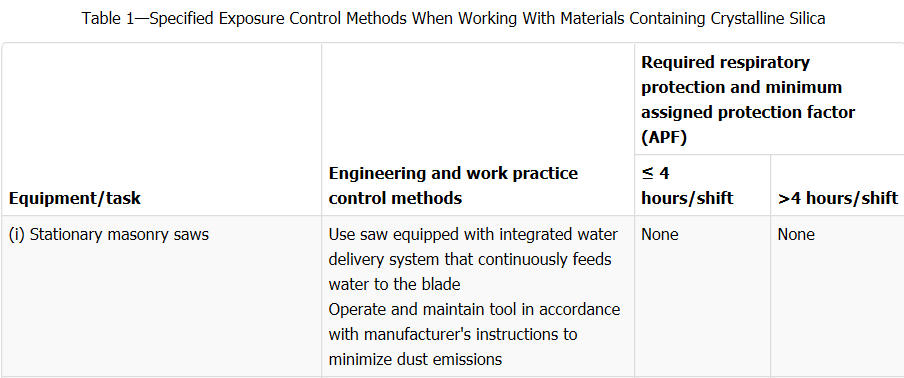

OSHA's new silica standard, CFR 1926.1153 lists approved exposure control measures for common operations that produce silica dust. It outlines 18 specific tasks and types of equipment in table format.

Table 1 has three main columns. The first lists the equipment used or task performed. The second lists the approved engineering and work practices control methods for those pieces of equipment or tasks. Then, the third column provides the level of respiratory protection required when those controls are in place. That third column is divided in two because the level of respiratory protection can change depending on whether the task is performed for more than four hours per shift.

The example (above) is for stationary masonry saws. OSHA's approved control methods include using a water delivery system and maintaining the tool appropriately. If those two things are done, no respiratory protection is required.

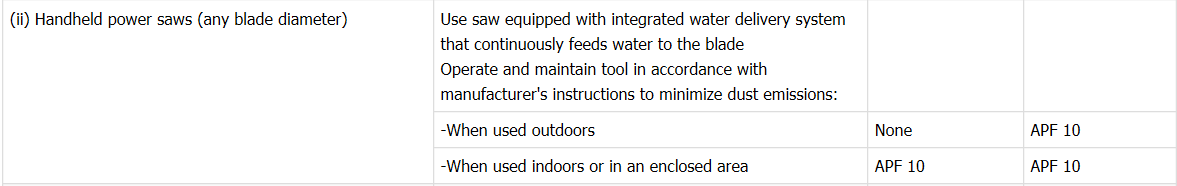

The example (below) for handheld power saws is a little more complicated. Again, the approved control methods are to use an integrated water delivery system and maintain the tool appropriately. However, the respiratory protection requirements are different for this tool.

When a handheld power saw is used outdoors for less than four hours per shift, no respiratory protection is required. However, if it is used outdoors for more than four hours, or indoors for any amount of time, a respirator with an assigned protection factor (APF) of 10 or greater must be worn.

OSHA has an APF chart available in 29 CFR 1910.134 that details the APFs for different respirators so that you can decipher which type is needed. It lists the basic types of respirators as well as columns for quarter mask, half mask, full facepiece, helmet or hood, and loose-fitting facepiece for each type. This chart will show which type of respiratory protection your employees need to be using. For example, an air purifying respiratory in a quarter mask would be an APF of 5, but as a full facepiece, would have an APF of 50. Follow these OSHA guidelines and create an exposure control plan in to ensure that the guidelines are followed.

What is included in an exposure control plan?

An exposure control plan is a written policy statement that explains what your company is going to do to prevent employees from being overexposed to silica dust.

The plan describes:

- Workplaces that involve exposure to silica.

- Control measures in place for the silica exposure, including engineering controls, work practices and respiratory protection.

- Housekeeping measures used to minimize silica dust.

- That medical surveillance must be provided to employees whenever silica exposure is at or above the action level (25 micrograms per cubic meter) for 30 or more days per year. Also, a baseline examination must be completed within 30 days of initial assignment to an area with silica exposure.

The plan must also state that the employer will:

- Inform employees whenever air sampling indicates that they have been overexposed to silica.

- Post warning signs at the entrance to areas with a silica exposure.

- Maintain records of medical exams and air monitoring data.

- Designate a competent person to oversee implementing the plan.

How can Texas Mutual help businesses meet OSHA's new silica standard?

Because Texas Mutual puts employee safety first, we're providing open access to our webinar on OSHA's Silica Standard that details how businesses can understand and stay compliant with the new regulations.

Also, our policyholders have exclusive access to:

- Download our Crystalline Silica Exposure Control Program from the safety resource catalog at texasmutual.com and use it to complete your company's policy.

- Email or contact us at safety@texasmutual.com if you have questions specific to your industry.

- Download our webinars, Toolbox Talks, posters and handouts on a variety of safety topics.

- Use our online videos and e-Learning courses for employee training on numerous topics.